BTB Engineering

Our ability to work with batch sizes from 1-offs to up to 300 car sets per year make us ideal prototyping and development partners for automotive OEMs. This is exemplified by our ability to supply specialist exhaust solutions for a variety of marques that include: Aston Martin, Audi, Jaguar, Land Rover, Mosler, Nissan, Porsche and Renault.

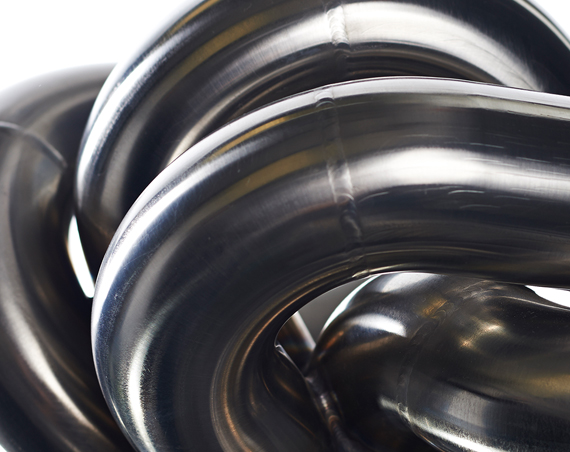

Computer controlled machinery can accept CAD data to bring your designs to production swiftly and accurately. Flexible production means we can be your one stop subcontractor for all tubular fabricated parts. Chassis parts, rollcages, fluid pipes, intake systems as well as exhaust manifolds, catalysts and silencers.

BTB has implemented the latest ISO 9001:2000 quality system that gives full traceability throughout the production process.

Our FARO portable coordinate measuring machine can be used to accurately measure prototype installations to speed up development time. We have experience of and access to a wide range of emissions testing and performance evaluation tools to back up design predictions.

Contact us today to see how we can meet your engineering needs.

Download the BTB Exhausts brochure

Download the Tube Bend Tool Chart

Engineering Video

Engineering Gallery